Duplexer Repair - Success this time?

My mistakes from 2022

When I first heard of Joe’s W1SK plan to put D-Star on Streaked Mtn I was pretty excited to help. I happened to be going to the Deerfield, NH hamfest so while there I found these gems. Joe then purchased them for his project.

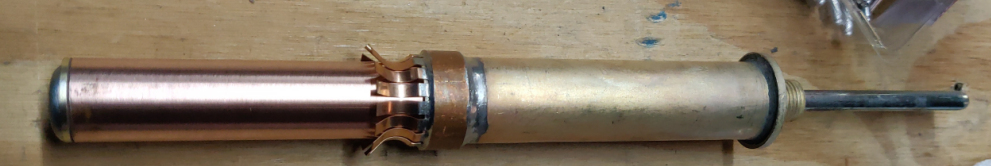

I told Joe I could get them tuned in for him. I can’t say I felt 100% confident due to my lack of experience but was pretty sure I could get the job done. Once the frequencies were finalized I started tuning. One of the 4 cavities I had a real hard time with. I would tune and tighten the lock nut only to have the tuning off again. I could tap the side of the can with a screw driver and the tuning would be all over the place. After fighting this battle for a long time I gave up and took the duplexer apart to see what was going on inside.

I found that the internal parts were covered with oxidation so I cleaned them up and re-assembled. After this process tuning went perfectly. I had this feeling I needed to take the rest of them apart but chose not to. I didn’t have enough rivets, the other cavities were tuning just fine so I called it good enough. This was a mistake.

Disaster

So the duplexers made the trip to Streaked Mtn where they performed very badly. The duplexers being the problem wasn’t immediately known so it caused lots of frustration and speculation. It also cost time and money. Eventually the equipment had to be removed for troubleshooting.

Cory KU1U delivered them to Randy K1XI who is a pro. He determined the duplexers, one cavity in particular, was bad. Once I got this word I felt responsible. I had a brand new TX/RX duplexers that had just arrived here for the KS1R D-Star repeater and I insisted they take them in exchange. The new duplexers were delivered to K1XI for a professional tuning, which was successful, and they are waiting to be put into service.

Another Repair Attempt

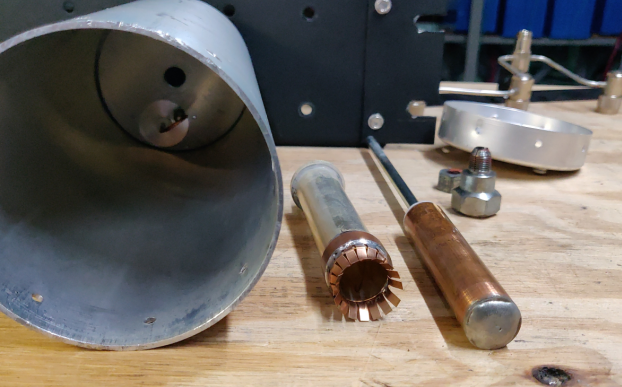

I asked for the duplexers back so I could try and repair them a second time. I also asked if the duplexer that was indicated as bad was the one I had attempted to repair but nobody knew that. My repair had gone very smooth and it was tough to tell. Once I had them in my hands I found that the one marked bad was NOT the one I had been inside and cleaned. This was good news and seemed to me to indicate I could clean the rest and have a working set of duplexers. Time to try.

It seems important that the connection between the copper plunger and the little copper fingers be as perfect as possible.

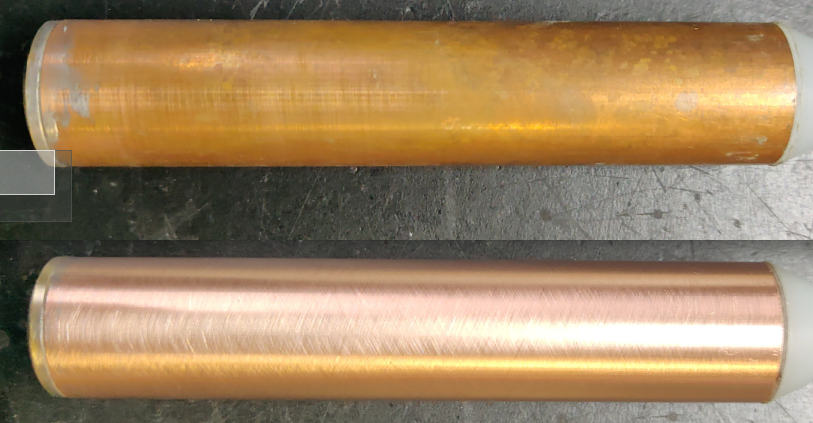

Here is a before and after picture showing just how much I was able to clean these things up.

Now you want to talk about a pain in the $%^@&)@. Getting the bottoms off of a couple of these made me think I was not going to be successful. It required a lot of pounding and prying, drilling, etc. I even had to wait for KB1IEF the XYL to get home to help.

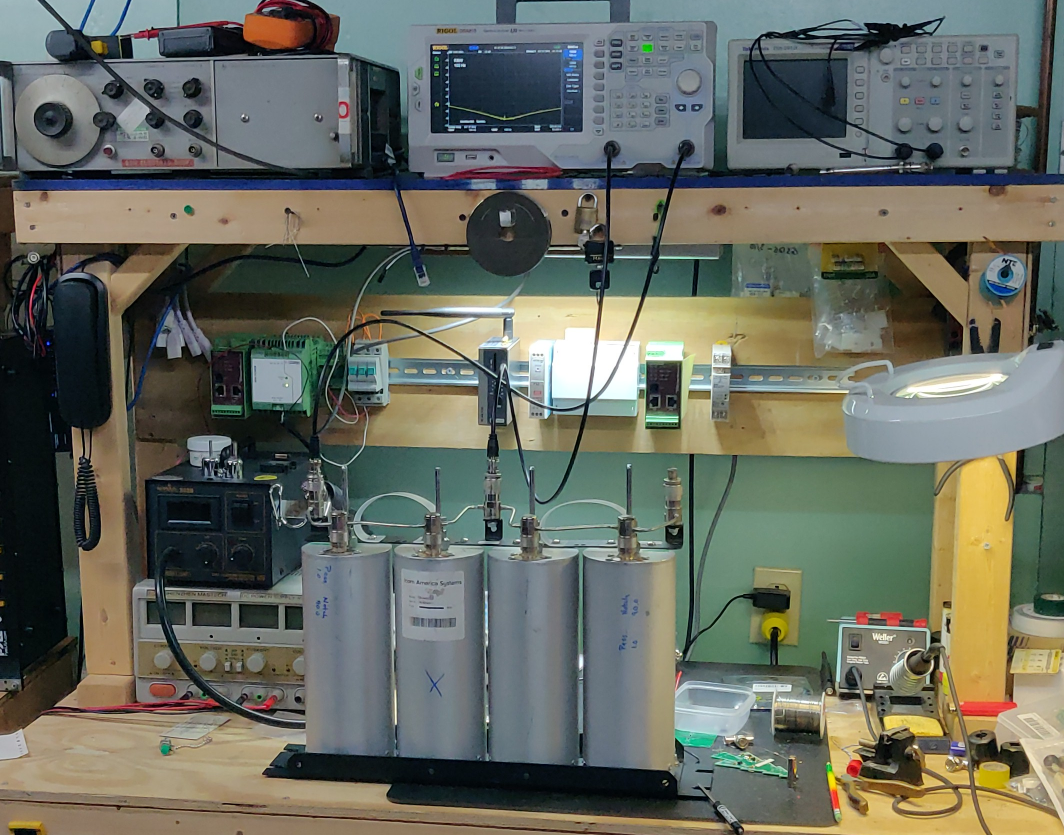

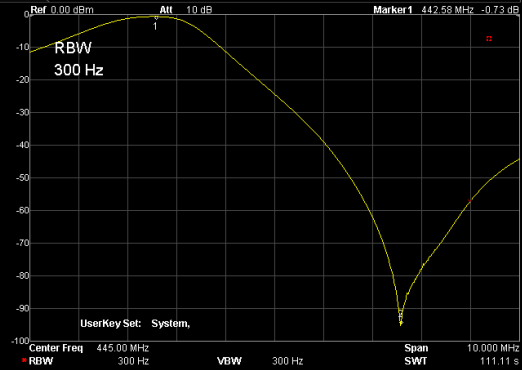

Success ??

They have now been reassembled, tuned, and installed. They seem to be working fine. Tuning went very quick and easy. I believe this to be a very good sign but I’m not calling success until more testing has been done and some time has passed. After putting them into service on our KS1R D-Star repeater I did a quick road trip and all went well.

Closing Thoughts

When dealing with a repeater, especially one that will be in a difficult to reach location, it has to be perfect. The price of less then perfect in anxiety, time, money, etc is just too high. I am happy with how this repair went but not sure I would want to see these duplexers headed for a difficult to reach repeater site. I would want someone in the business, like K1XI to have a look first.